Water Jet Cutting Auburn WA can provide precise cutting of soft materials for many types of projects. It is especially useful for fabricating machine parts when an abrasive is added to the water during the cutting process. Specialty Metals has everything on site to process an order, including the materials and an all-inclusive shop that is run by an experienced team.

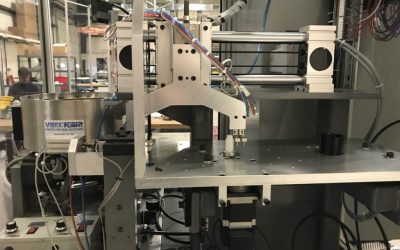

Water Jet Cutter

Cuttings done with a water jet cutter are precise and accurate. A water jet cutter uses water that is under extreme pressure, usually around 60,000 PSI, to skillfully slice through a variety of soft materials, such as wood, foam, rubber and paper. A water jet cutter can also be used to cut through harder surfaces, such as metal, glass and stone when the addition of an abrasive, known as garnet, is added to the pressurized water.

Garnet

The type of garnet that is commonly used for Water Jet Cutting in Auburn, WA is red garnet. This gemstone is relatively hard, and when it is broken down, the edges become very sharp and abrasive. The razor-like quality, when it is reduced to sand like consistency, makes garnet an excellent choice to use in the water jet cutter when carving through rigid surfaces.

How It Works

Water jet cutting takes pressurized water to slice through whatever material is being used for a specific project. This tool is extremely accurate and leaves crisp, sharp edges wherever it slices a surface. The process is similar to how erosion breaks down surfaces in nature, but the water jet cutter applies this technique on an accelerated level.

Uses

Water jet cutting is used in a variety of ways, such as making precision parts for aerospace, cutting out sign logos and images, creating machine parts and making deep cuts into thicker materials that cannot be sliced with other methods. This process can also be used to cut through granite, marble, tile, brass and ornamental irons. It can create intricate designs and patterns in all types of metal and stone and doesn’t require heat to do so.

When the project calls for precision lines and accuracy, consider using a water jet cutter to get the job done. For more information regarding how water jet cutting works and what it can do for you, please Visit website.