Fabrication can include various processes, such as engineering, designing, shearing, sawing, laser and plasma cutting. It can likewise incorporate machining, framing, welding, and completing, and part collection. The last part of a steel fabrication job is the testing the finalized product. This is a crucial step that all skilled stainless steel fabrication must do before allowing a product to leave the shop.

Utilization of Strength and Equipment

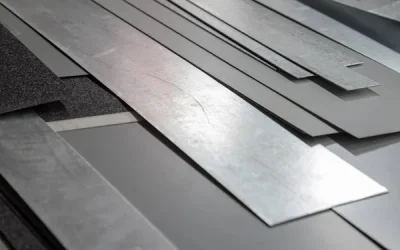

Metal fabricators typically have the capabilities to manufacture carbon steel, stainless steel, and aluminum. Some manufacturers even incorporate machining, precision laser cutting, plasma cutting, turret punching, special forming, and welding with CNC controlled hardware. The CNC gear used usually comprises of computer controlled turning, milling, and processing machines that produce precision machined parts.

Plasma cutting is finished with a top quality plasma cutter. Thick plates of material are cut with complex shapes and tight determinations to finish any project, no matter how substantial.

Precision laser cutting can cut exact, intricate parts and also is able to complete complex surface carving plans. Many fabricators are able to create a lot of items that are both precise and uniform and can finish a project within a timely manner.

Stainless steel fabricators can finish projects that incorporate sheet metal manufacturing, oil field creation work, and truck body manufacturing. Should the customer come in with thoughts, fabricators often offer assistance with conceptualization and design.

Quality and dependable fabricators will finish a venture through exhaustive and exact work that focuses on the subtle elements. For example, Wisconsin Metal Fab we has the capacity to move any venture through each phase of creation, regardless of how overwhelming it may seem.